Our Process

Four steps from existing space to finished restaurant

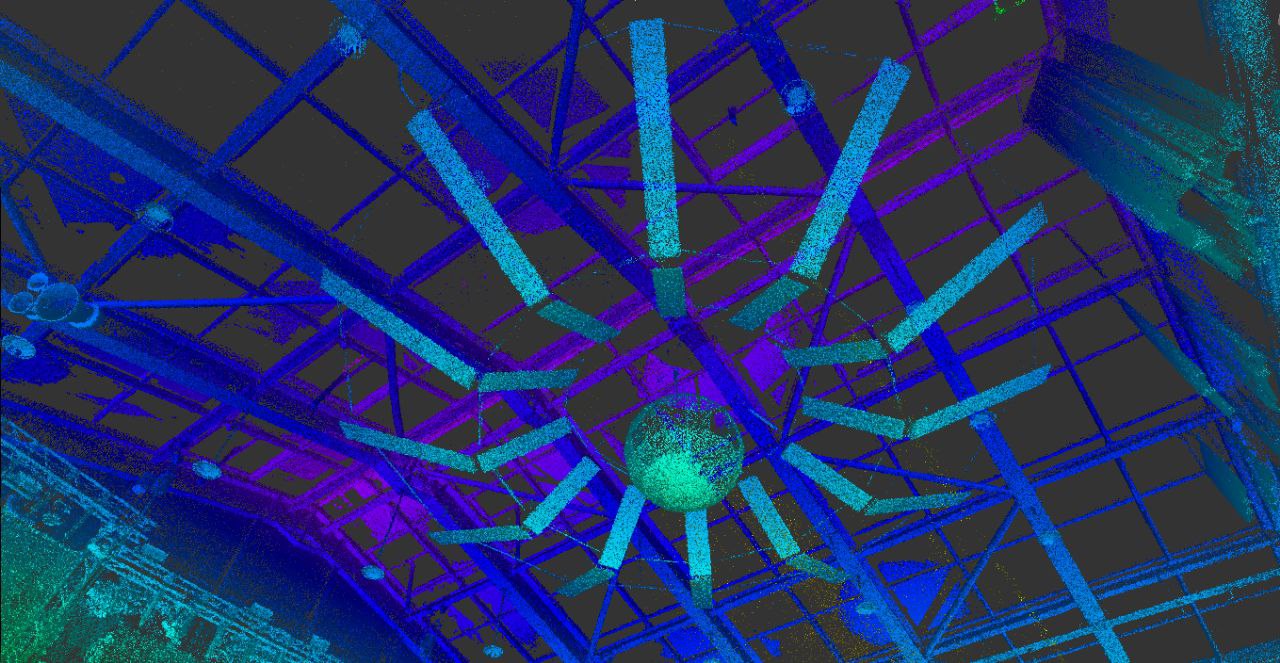

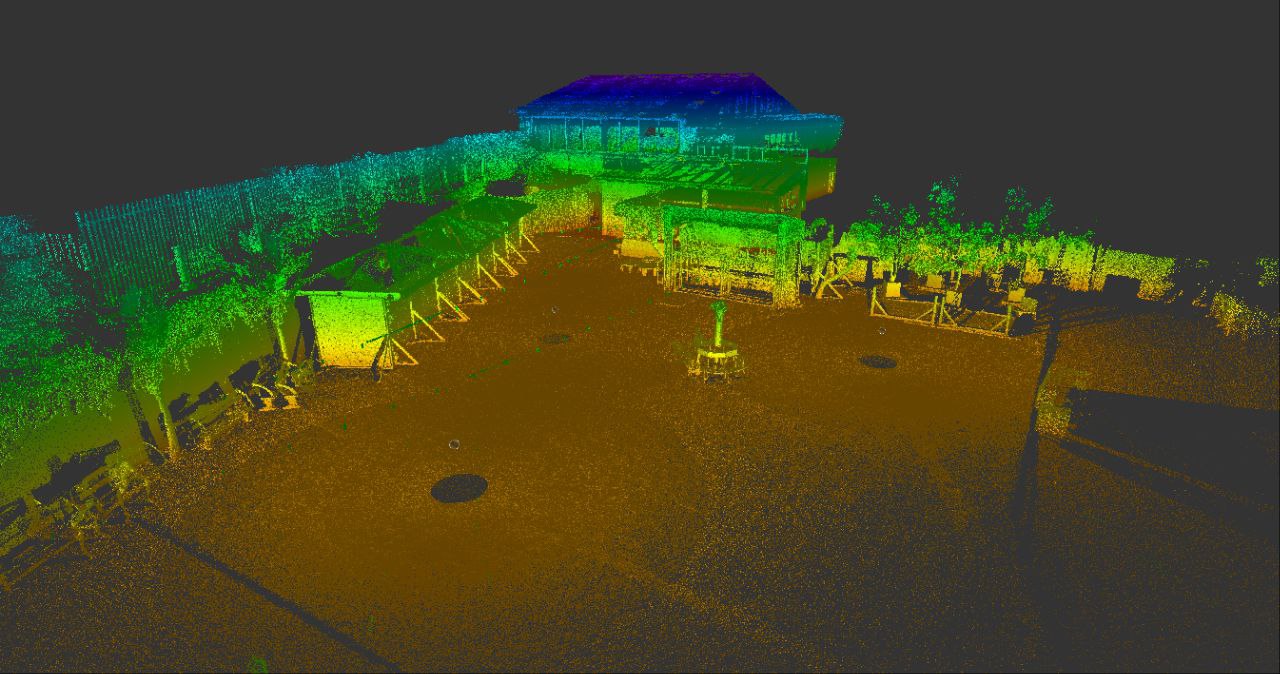

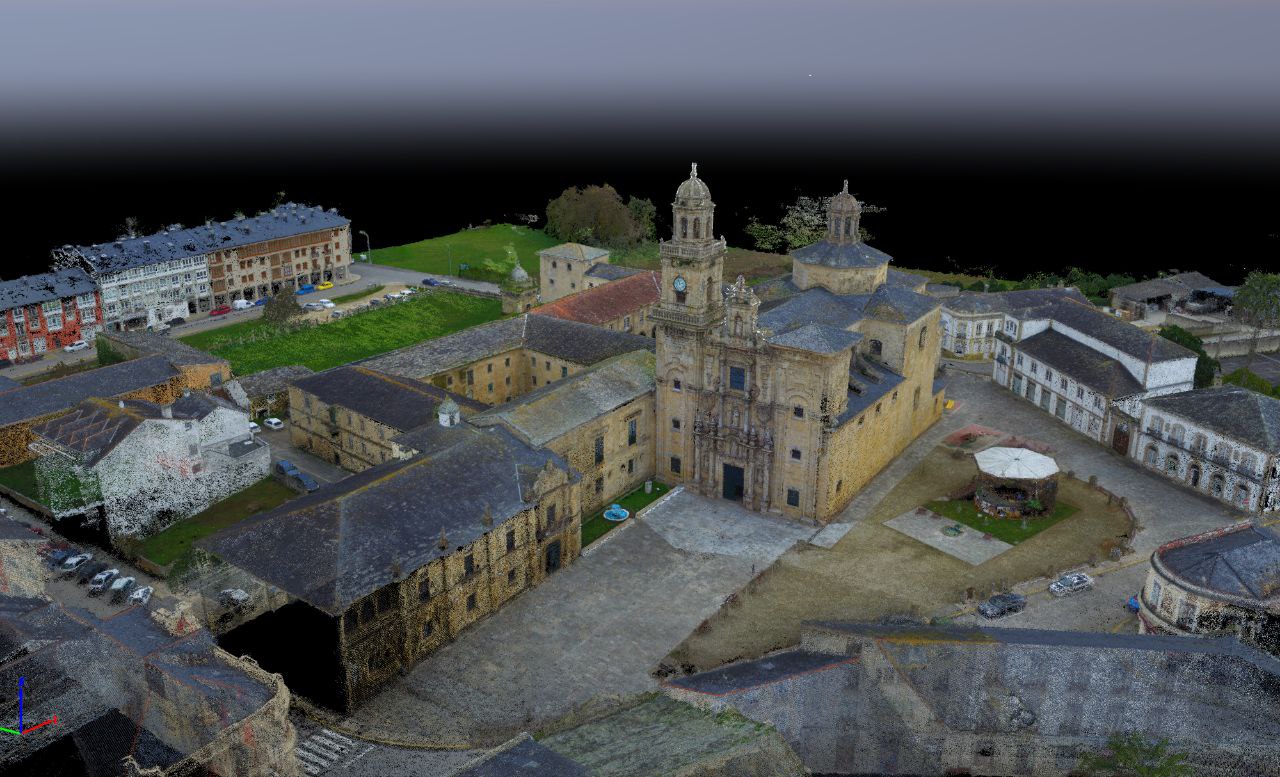

LiDAR Scanning

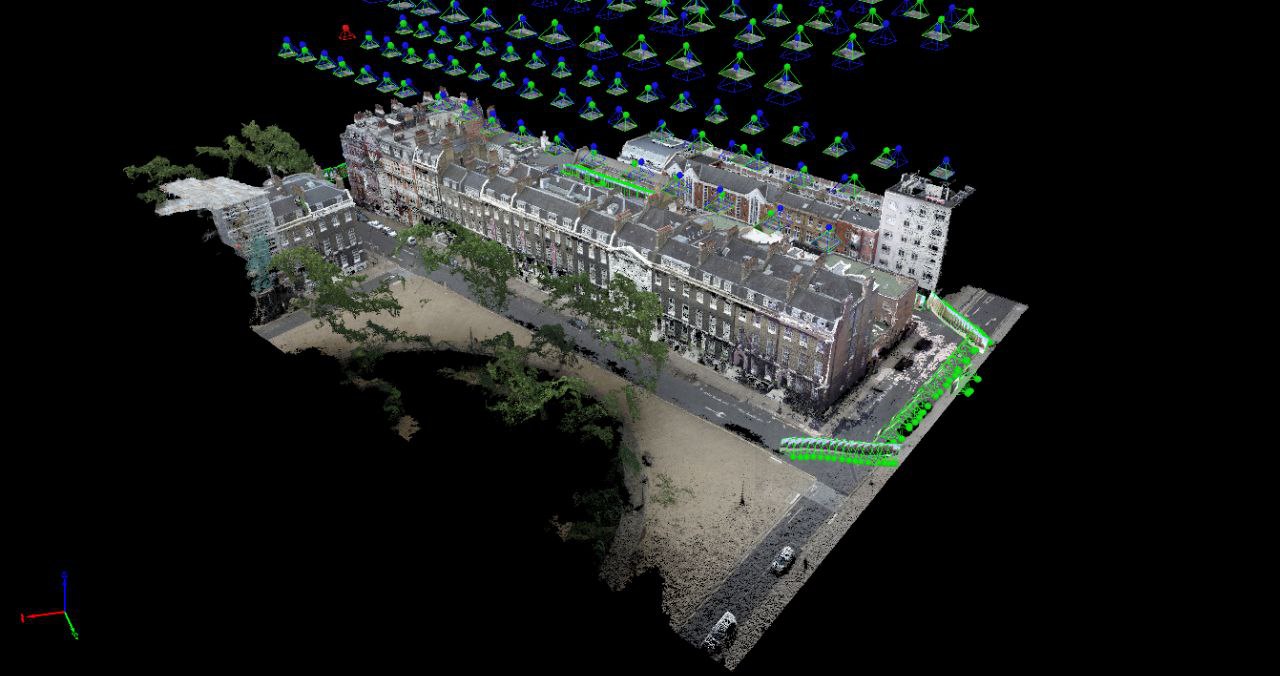

The LiDAR scanner is brought on site to capture the entire space in high-resolution 3D. It sits on a tripod and rotates, firing millions of laser points to map every surface, corner and obstacle with millimetre precision. Multiple scan positions ensure complete coverage; nothing is missed.

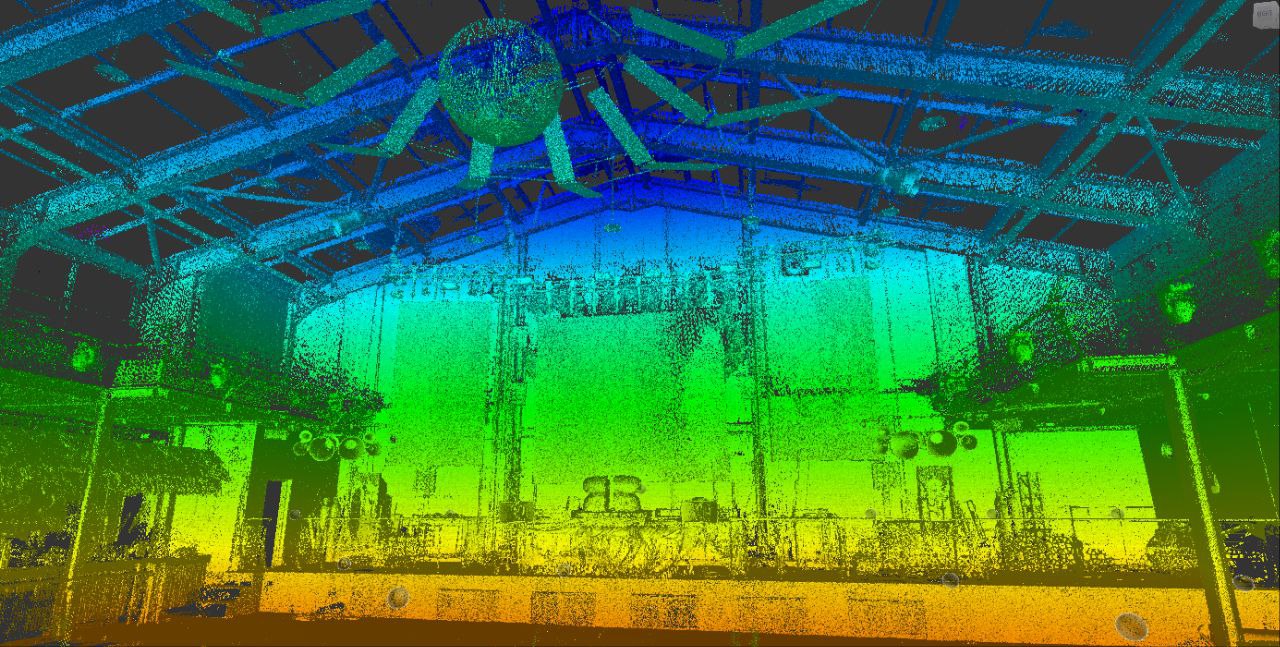

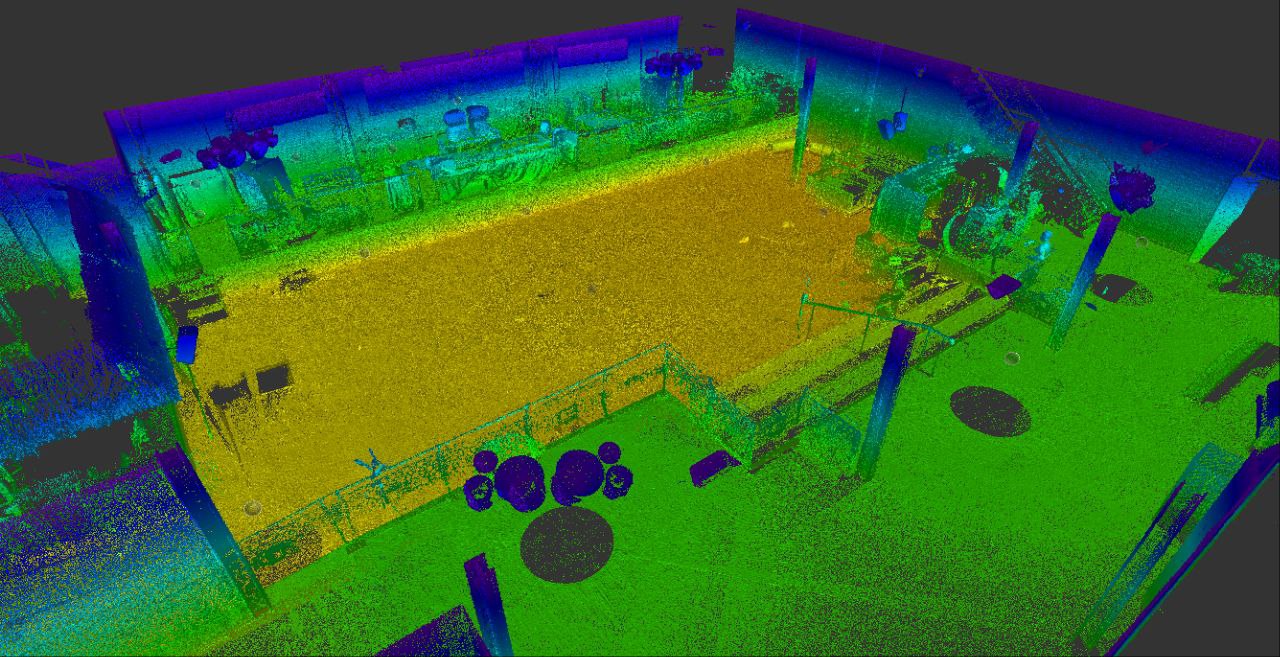

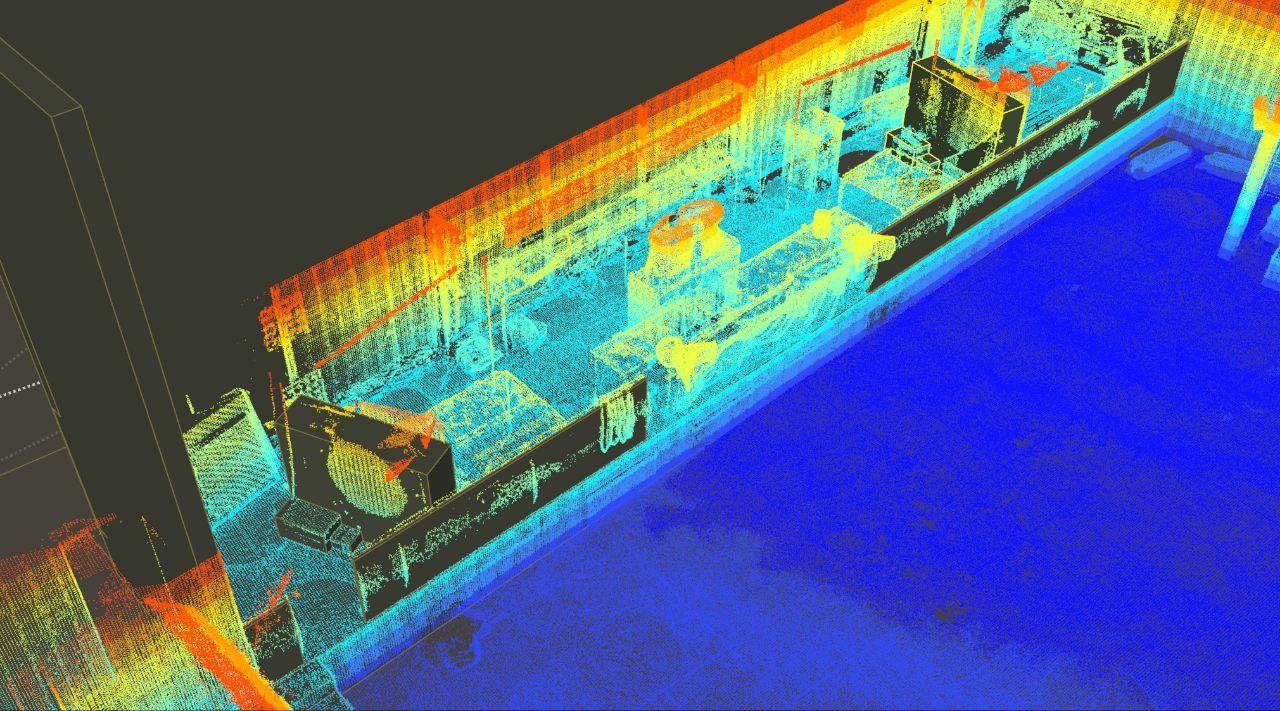

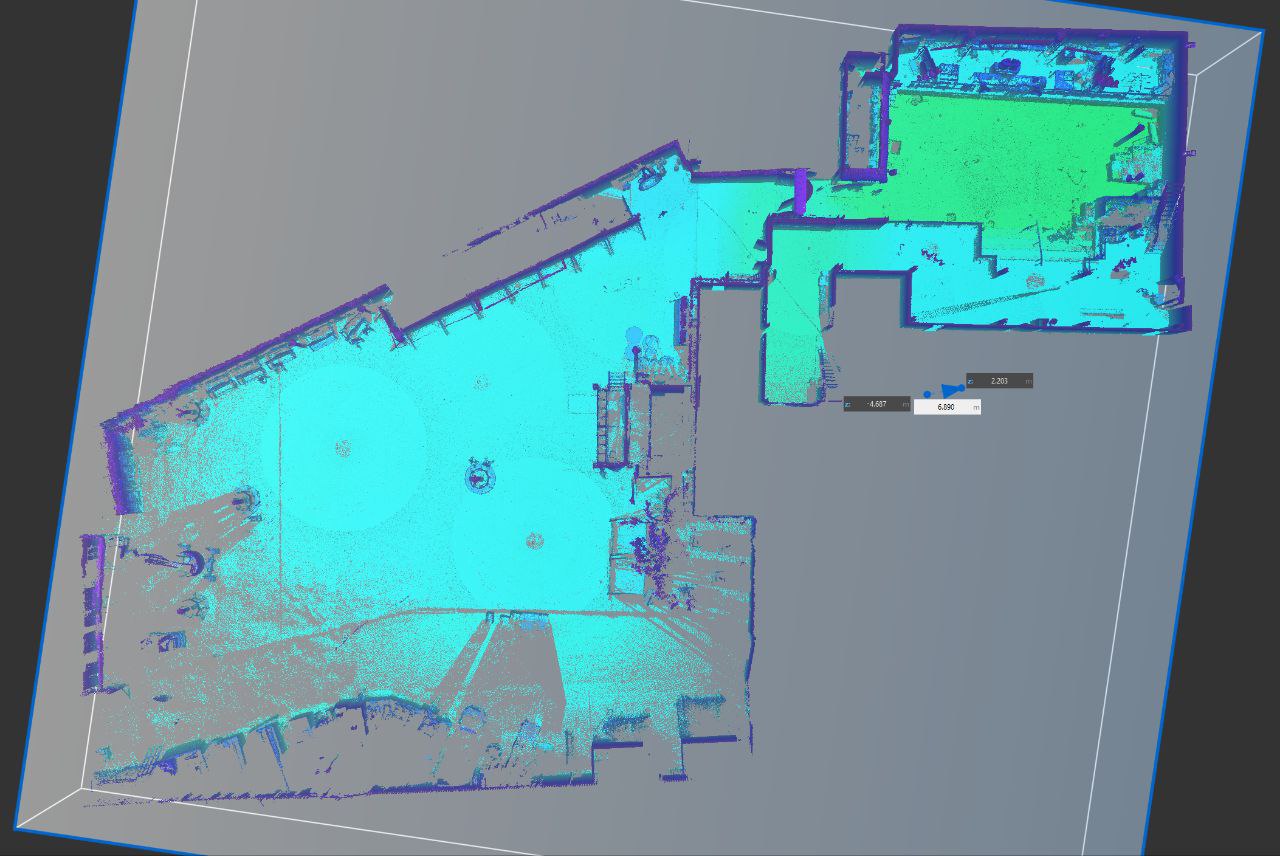

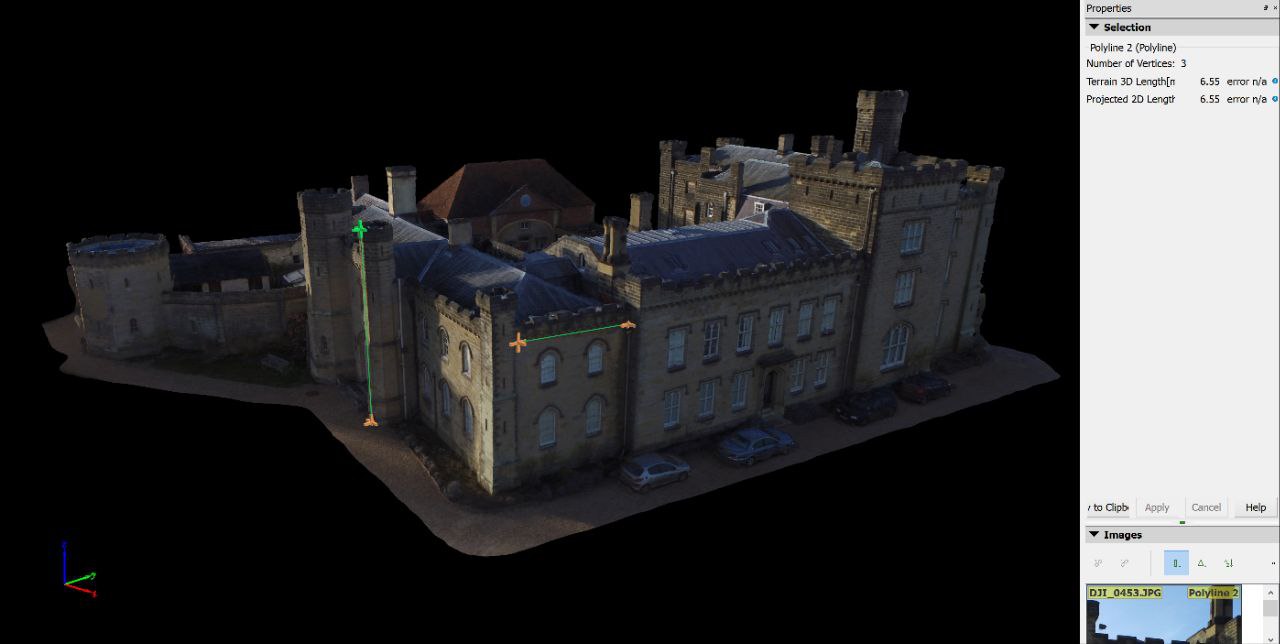

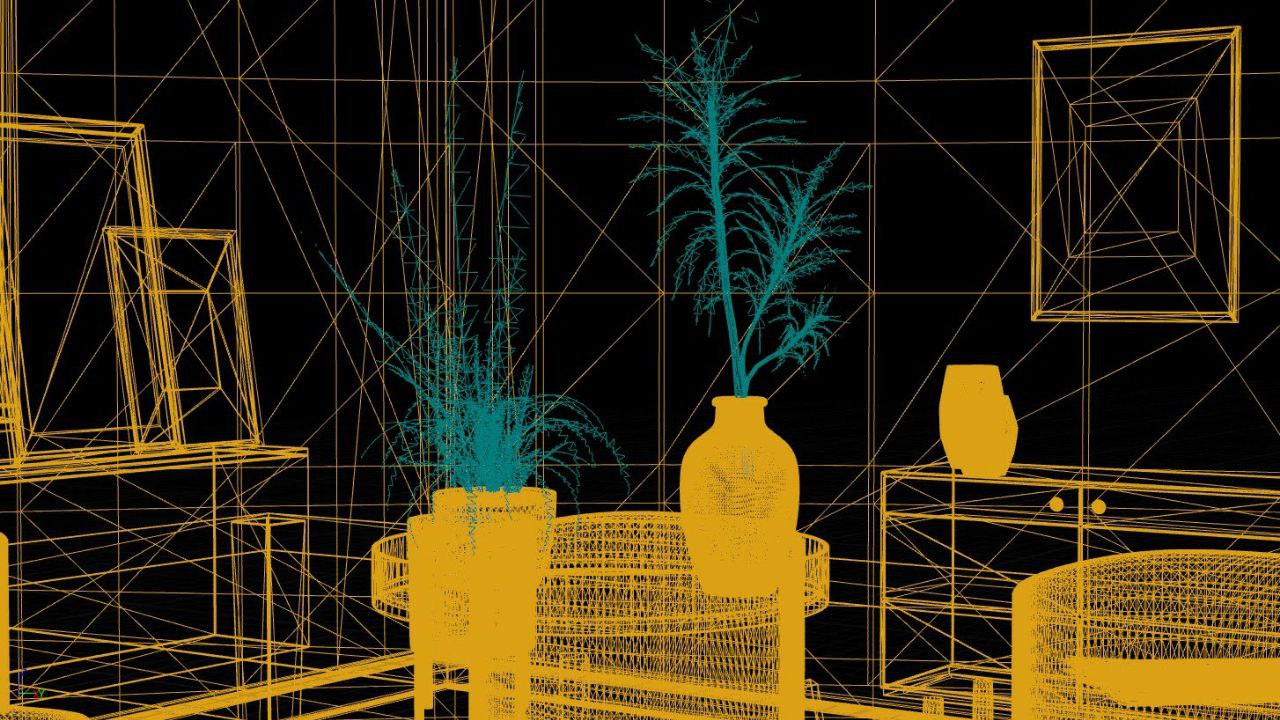

Point Cloud Data

The scanner produces a detailed point cloud: millions of coloured data points that form a precise 3D map of the space. We can view floor plans from above, inspect ceiling structures, measure distances between any two points, and identify issues that would otherwise only surface mid-build. This data is the single source of truth for the entire project.

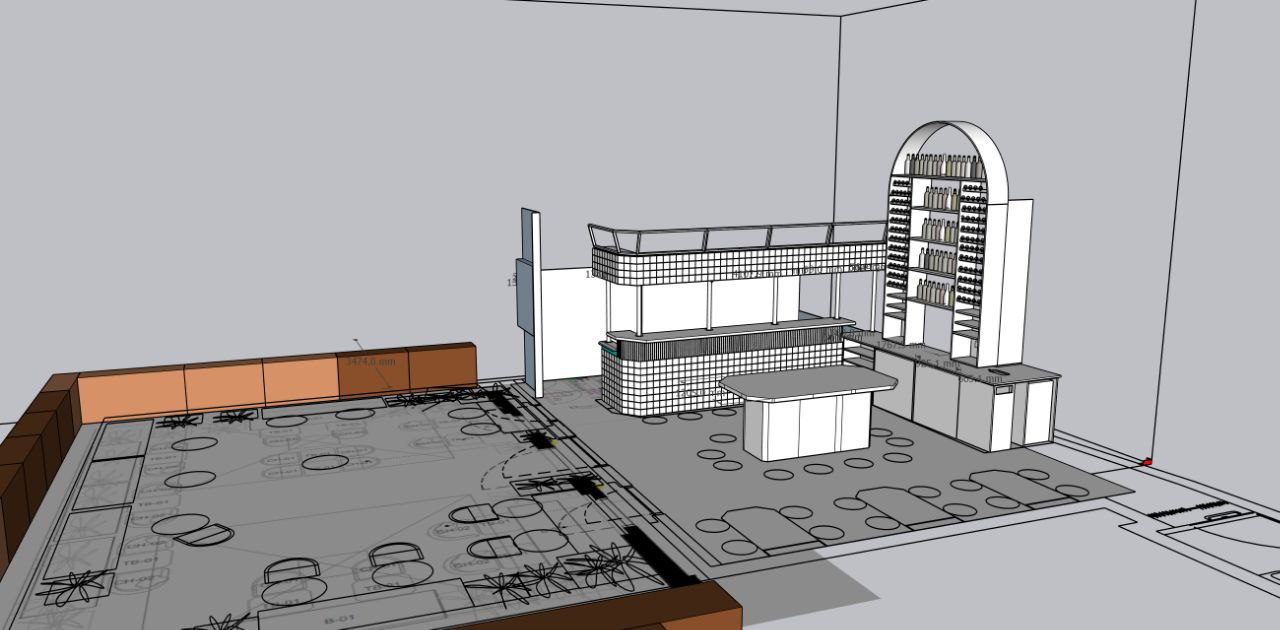

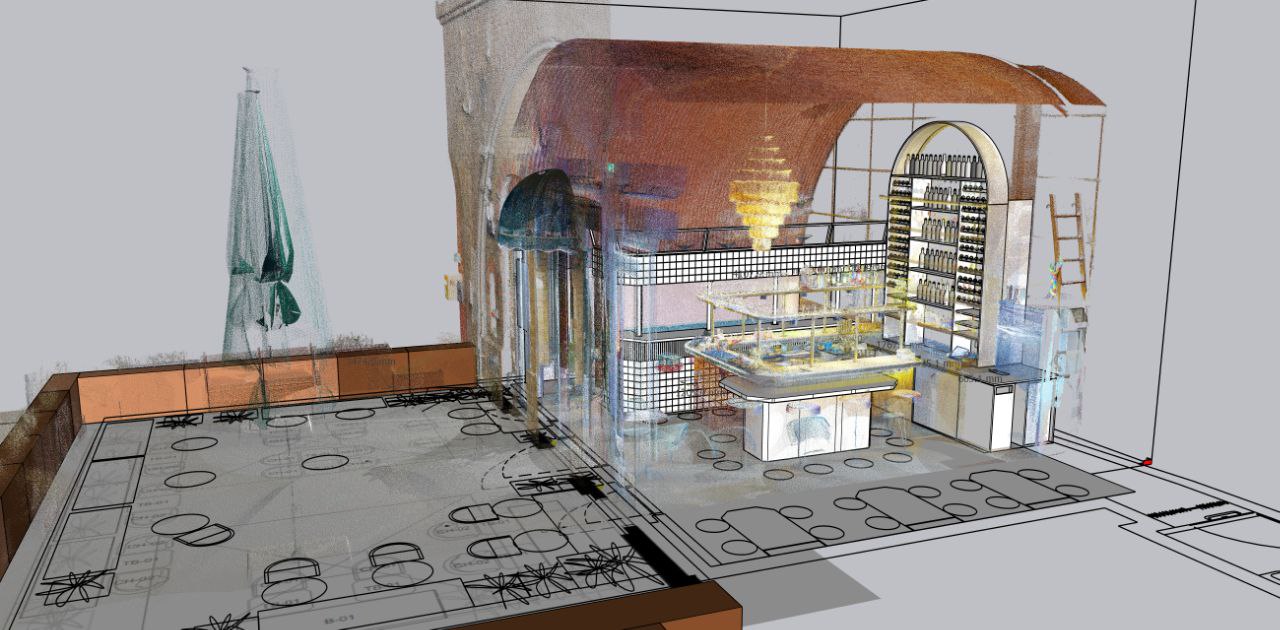

3D Design Modelling

Using the point cloud as a foundation, we build accurate 3D models in SketchUp, designing the bar, kitchen, seating and every detail within the real dimensions of your space. We then overlay the design onto the LiDAR data, so you can see exactly how the finished restaurant will look inside the actual building. Changes are made digitally, not on site.

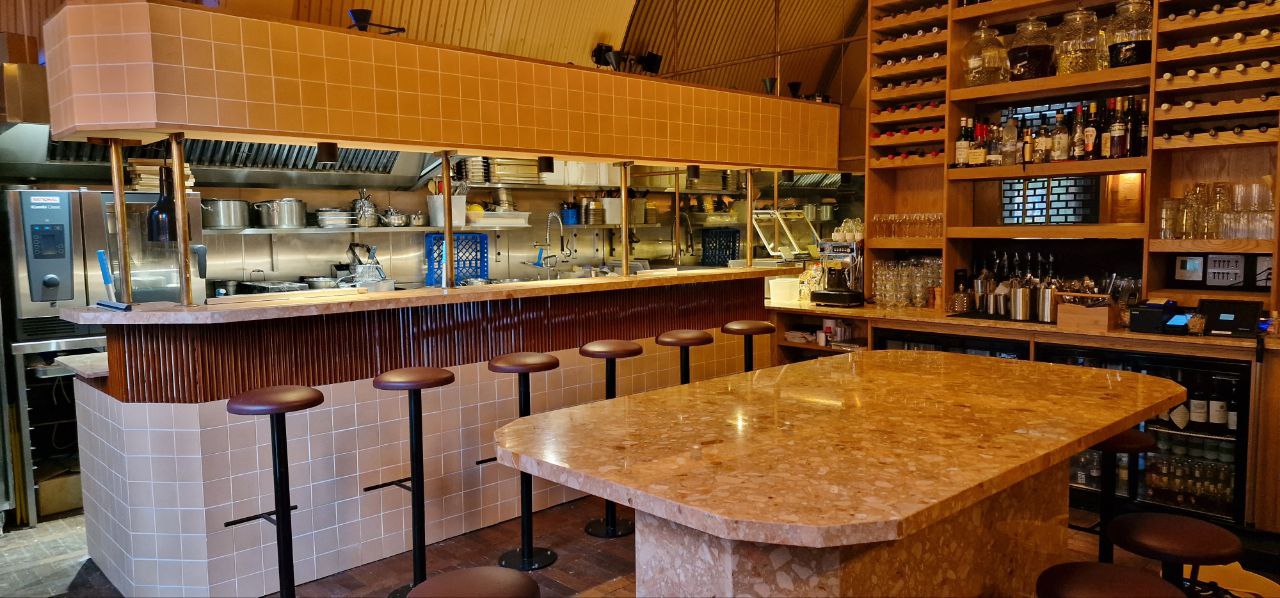

The Finished Build

Then we build it. Because the planning was precise, the construction is precise. What you saw in the 3D model is what you get in reality: a finished restaurant that matches the design, delivered on time and on budget.